- Home

- Products

- Ceramic Powder

- Alumina Powder

High Quality Alumina Powder Products >>>

Alumina is one of the most widely adopted ceramic materials. It is composed of Aluminum Oxide (Al2O3), which is the chemical compound of aluminum and oxygen. It offers electrical insulation, high temperature and chemical resistance, thermal conductivity and also provides superior abrasion resistance.

Purity levels for alumina range from 85% to 99.9%, supporting temperature ranges of: 100°C to 1600°C.

Related Products

-

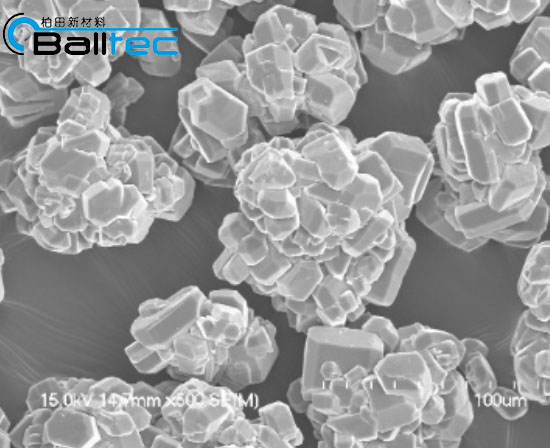

High Purity Aluminum Hydroxide

The product uses high-purity aluminum ingots as the main material and it is prepared by the hydrolysis method. It has the characteristics of high purity and particle size stability. This product is white powder with 9.998% purity, odorless and tasteless, soluble in dilute mineral acids such as hydrochloric acid, and it will begin to endothermic and decompose when heated to 220°C, releasing three crystal waters, non-toxic, odorless, good dispersibility, whiteness High, low iron content. And it can be used for gastrointestinal anti-acid raw materials, rubber, wire and cable and other flame-retardant fillers and fillers for artificial agate products.

Details -

High Purity Alumina Powder for Intraocular Lens

On the basis of the salt water hydrolysis method, the "improved direct hydrolysis method" high-purity alumina preparation technology, namely the high-purity aluminum direct hydrolysis method, was successfully developed through technological innovation. This technology replaces aluminum foil with high-purity and high-activity aluminum powder, and replaces isopropanol with high-purity water. The aluminum powder reacts with pure water at a certain pressure and temperature to form aluminum hydroxide, which is then dried and roasted to obtain high-purity aluminum oxide.

Details -

High Purity γ-Alumina

This product uses high-purity aluminum as the main material and is prepared by the hydrolysis method. Y-type alumina is insoluble in water, and can be dissolved in strong acid or strong alkali solution. When heated to 1200℃, it will be completely converted into type alumina, y-type alumina It is a kind of porous material, mainly used as the raw material of porous ceramics and bio-ceramics, high-efficiency catalysts, catalyst carriers and automobile exhaust purification materials.

Details -

High Purity Alumina Powder for Transparent Ceramics

The product uses high-purity alumina as the main material and is prepared by the hydrolysis method. It has the performance characteristics of high purity, stable particle size, and spherical powder shape. It can be used for the preparation of transparent and translucent alumina ceramic tubes, ceramic substrates, etc. Because the AO ceramic body has a high melting point, it is difficult to form, and its lattice constant is close to that of AO, so it can form a solid solution with AO. At the same time, they are variable-valence oxides. Due to the variable-valence effect, AO porcelain produces defects, activates the crystal lattice, and promotes the formation of porcelain.

Details -

High-purity Ultra-fine Alumina Powder Series for Lithium Battery Separator

During battery charging and discharging, the integrity of the separator can still be maintained, preventing large-area positive/negative short-circuit phenomena and due to its thermal shutdown mechanism, it can greatly improve the safety of lithium batteries.

Details -

Alumina Polishing Powder

The main component of alumina polishing powder is -AO powder calcined at high temperature. It also contains auxiliary components such as dispersant, suspending agent, lubricating agent, emulsifier, etc. It is mainly used in tableware industry, jewelry industry, auto parts, optical lenses, and machinery and Industries that require surface treatment, such as electrical accessories.

Details

Русский

Русский Français

Français Español

Español English

English

Welcome to send your message to us