- Home

- Products

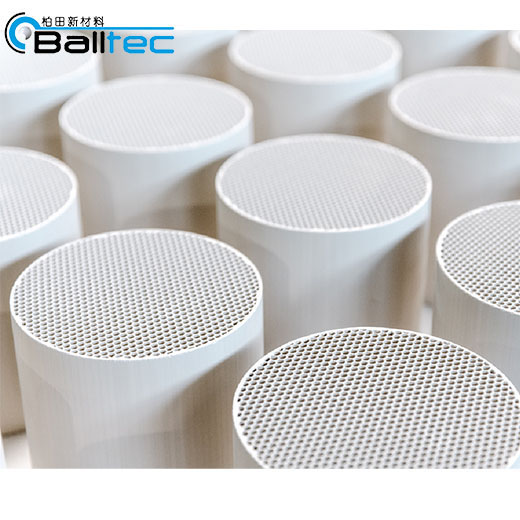

- Ceramics Honeycomb

- Honeycomb Ceramic Catalyst Substrate

Honeycomb Ceramic Catalyst Substrate

Product Description

Honeycomb ceramic catalyst substrate is used for gasoline vehicle catalyst converter of the exhaust gas purification treatment after coating catalyst. It can catalyze and purify the exhaust. The main material of the honeycomb ceramic catalyst substrate is cordierite. It can catalyze and purify the exhaust gas of the vehicle. We could provide 300cpsi, 400cpsi, 600cpsi honeycomb ceramic catalyst substrate. The height is within 200mm. The shape of the cross section could be round shape, ellipse shape, runway shape, pear shape or other shapes as per requirement of customers.

The features of the cordierite honeycomb ceramic catalyst carrier as below:

• Thin hole wall

• Large surface area

• Low back pressure

• Small coefficient of thermal expansion

• Good thermal impact resistance and good thermal shock resistance

• Good matching with various catalyst active composition

• Good performance of cold start

• Low starting ignition temperature

• High speed of temperature raise

• Low air resistance

• High conversion efficiency

Specification and Size

| CPSI | Hole wall | Hole size | Hole area | Hole ratio | Surface area | Bulk density |

| 300 | 0.25mm | 1.22mm | 1.48mm2 | 67% | 2200m2/m3 | 500kgs/m3 |

| 300 | 0.22mm | 1.25mm | 1.55mm2 | 70% | 2260m2/m3 | 500kgs/m3 |

| 300 | 0.19mm | 1.28mm | 1.63mm2 | 74% | 2310m2/m3 | 500kgs/m3 |

| 400 | 0.23mm | 1.04mm | 1.08mm2 | 67% | 2579m2/m3 | 480kgs/m3 |

| 400 | 0.20mm | 1.07mm | 1.75mm2 | 71% | 2654m2/m3 | 480kgs/m3 |

| 400 | 0.17mm | 1.10mm | 1.21mm2 | 75% | 2728m2/m3 | 480kgs/m3 |

| 600 | 0.23mm | 0.81mm | 0.65mm2 | 61% | 3002m2/m3 | 580kgs/m3 |

| 600 | 0.20mm | 0.84mm | 0.70mm2 | 65% | 3114m2/m3 | 580kgs/m3 |

| 600 | 0.17mm | 0.87mm | 0.75mm2 | 70% | 3225m2/m3 | 580kgs/m3 |

Physical and chemical property

| Item | 200cpsi | 400cpsi | |

| Compressive strength Mpa | A Axis | 15 | 15 |

| B Axis | 1.5 | 1.5 | |

| C Axis | 0.2 | 0.2 | |

| Water absorption % | Min | 18.6 | 17.8 |

| Max | 23.4 | 20.7 | |

| Average | 22.1 | 19.6 | |

| Pore volume | Cm3/g | 0.18-0.24 | 0.18-0.24 |

| Thermal expansivity | 20-1000℃ 10-6/K | 1.5 | 1.8 |

| Thermal conductivity | 25-600℃ W/m.K | 1.5-1.6 | |

| Specific heat J/g.K | 100℃ | 0.8 | 1.5-1.6 |

| 200℃ | 0.95 | 0.95 | |

| 300℃ | 2 | 2 | |

| Soften temp. | ℃ | 1380 | 1380 |

| Continuous high-temp. Durability % (After 100 hours) | 1200℃ | 0.5 | 0.1 |

| 1450℃ | 2 | 2.5 | |

| Heat consumption rate ℃/min | 20-1000℃ | 5 | 5 |

Physical and chemical property

| Item | Stoneware | Cordierite | Mullite-cordierite | Mullite |

| SiO2 % | 69-71 | 46-48 | 45-50 | 27-28 |

| Al2O3% | 18-30 | 34-37 | 45-50 | 70-71 |

| MgO % | 0.15-0.20 | 12.0-14.0 | 6.0-9.0 | — |

| K2O+Na2O+CaO % | 3.3-3.3 | 2.5-2.9 | 0.7-0.9 | 0.8-1.2 |

| Fe2O3 % | 0.7-0.9 | 0.7-0.9 | 0.5-0.7 | 0.5-0.7 |

| TiO2+BaO % | 0.2-0.25 | 0.3-0.4 | — | — |

Русский

Русский Français

Français Español

Español English

English

Welcome to send your message to us