- Home

- Products

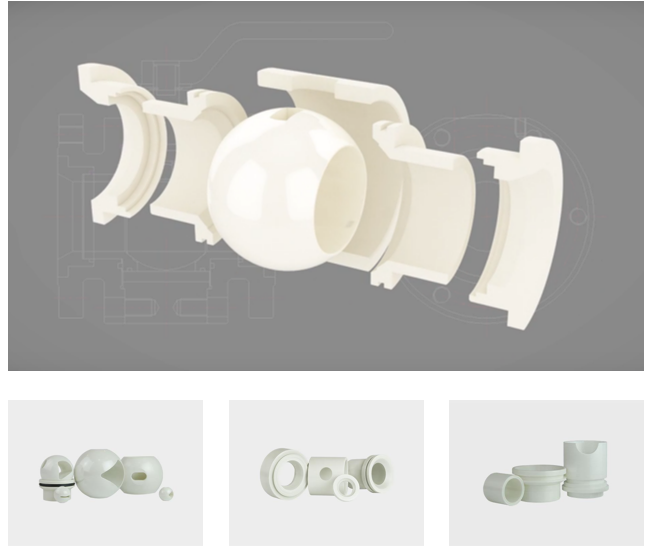

- Ceramic Structure

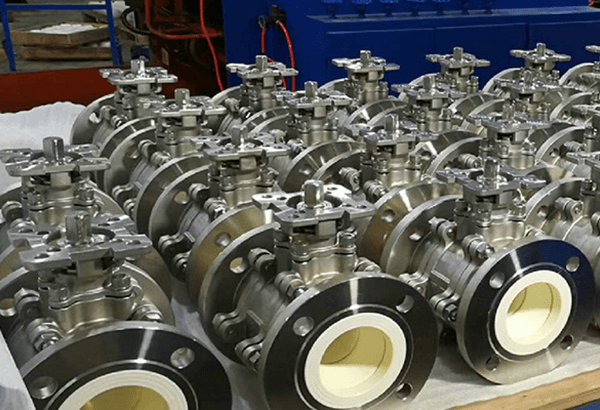

- Ceramic Ball Valves

Ceramic Ball Valves

Product Description

Zirconia ceramic ball valve is a high-tech product developed by our company on the basis of the national seven-five-year scientific and technological achievements and high technology and equipment research and development. The national new product certificate was obtained in 1995 and five patents were granted. In addition to the most advantages of metal balls, the zirconia ceramic ball valve has superior corrosion resistance, high temperature resistance, wear resistance and erosion resistance. It is widely used in various acid-base salt gas, liquid, high-temperature steam and mud transportation systems in petrochemical, metallurgy, papermaking, power stations, oil refining and other industries. It is an ideal substitute for titanium valves and nair valves in strong corrosive situations. And we can design all kinds of special ceramic valves according to clients’ requirements.

Ceramic Structure--Ceramic Ball Valves

Properties

| Nominal Pressure | ≤4.0Mpa |

| Inside Nominal Diameter | DN 10~250mm |

| Working Temperature | ≤400℃ |

| Sealing Form | Ceramic hard sealing and PTFE soft sealing |

| Manner of Working | Manual, Pneumatic, Electronic |

| Functional Classification | O-type sealing ball valve, V/O-type adjusting ball valve |

| Valve Body | Carbon steel, Stainless steel, Nickel phosphorus plating on carbon steel. |

| Flange Standard | GB, ANSI, JIS |

| Inside Ceramic Linerd | ZTA, ZrO2 |

| Ball and Seat | Y-TZP, Ce-TZP |

| Applied Environment | Acid-base salts other than hydrofluoric acid, high corrosion and high wear occasions, medium and low temperature environments. |

Русский

Русский Français

Français Español

Español English

English

Welcome to send your message to us