- Home

- Products

- Molecular Sieve

- Zeolite Honeycomb Molecular Sieve

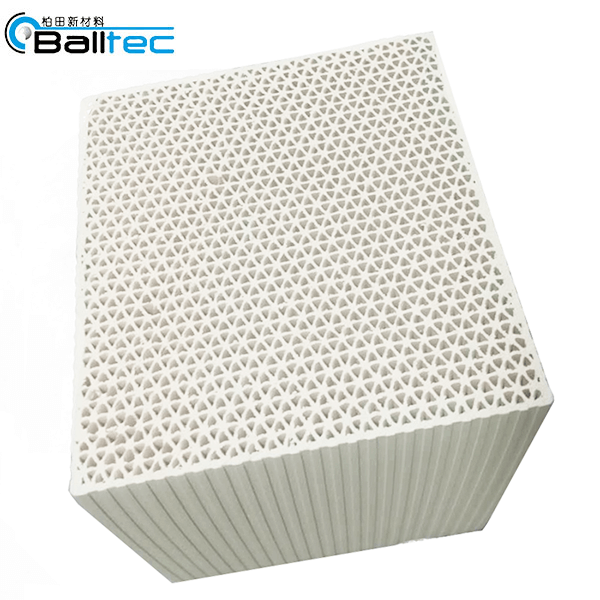

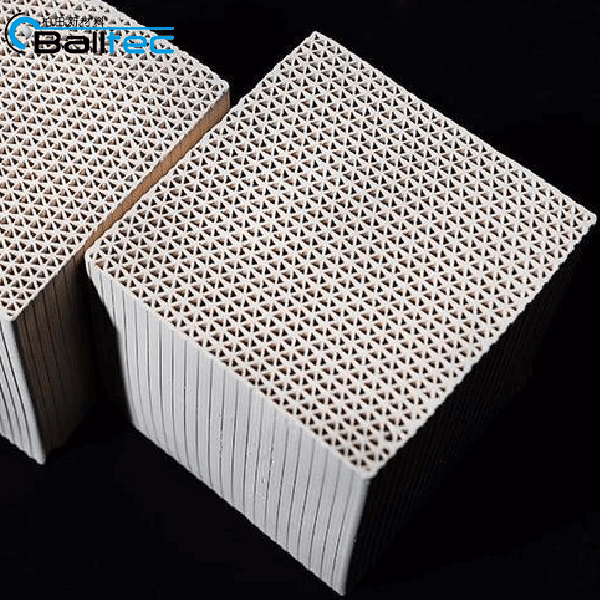

Zeolite Honeycomb Molecular Sieve

Product Description

Honeycomb zeolite molecular sieve is a kind of high-efficiency molecular sieve carrier with good adsorption performance, no secondary pollution, and high temperature regeneration. It has an efficiency of 40% higher than that of similar activated carbon. It has been widely used in the fields of adsorption, separation, catalysis and environment. It is more suitable for large air volume, low air volume and high-concentration organic waste gas treatment.

Compared with other adsorbents, molecular sieves have the following advantages:

Strong adsorption selectivity: Being an ionic adsorbent, the pore size of the molecular sieve is neat and uniform. Therefore, it can selectively adsorb according to the size and polarity of the molecule. If it can effectively remove ethylene and propylene from saturated hydrocarbons, it can also effectively remove acetylene from ethylene, which is determined by its strong polarity.

Strong adsorption capacity: Even if the composition concentration of the gas is very low, it still has the adsorption capacity and a large adsorption capacity at a higher temperature. Under the same temperature conditions, the adsorption capacity of molecular sieves is larger while other adsorbents are greatly affected by temperature. Because of the above advantages, molecular sieves have become a very good adsorbent, widely used in the production of basic organic chemicals and petrochemicals. In the treatment of harmful gases, it is also commonly used in SO2, NOX, CO, CO2, NH3, CCI4, Purification of water vapor and gaseous hydrocarbon waste gas.

It can be regenerated at high temperature, with high regeneration efficiency and high safety. The use of shaped molecular sieve as the adsorbent for waste gas treatment will become the mainstream. The technology of molecular sieve as a carrier has been widely used abroad. Molecular sieves can be designed and applied according to different pollutant concentration and particle size.

Features

The molecular sieve carrier has uniform micropores, and the pore molecular sieve carrier has uniform micropores, and its pore size is equivalent to the general molecular size. It is an inorganic microporous material composed of SIO2, AI2O and alkaline metals or alkaline earth metals, and its inner pore volume accounts for the total volume. The specific surface area is 300-1000㎡/g. It has the characteristics of high temperature resistance, non-flammability, good thermal stability and hydrothermal stability. Its pore size is below 2μm for microporous molecular sieve, and 2-50μm for medium Porous molecular sieve (large pore molecular sieve above 50μm), mesoporous molecular sieve has extremely high specific surface area, regular and orderly pore structure, narrow pore size distribution, continuously adjustable pore size, etc., making it difficult to complete in many microporous molecular sieves It plays a role in the adsorption and separation of large molecules, especially in catalytic reactions.

Physical Properties

| Property | Micropores | Mesopores |

| Dimensions (mm) | 100x100x100 | 100x100x100 |

| Aperture count(cm2) | 16 | 16 |

| Hole Plating Thickness(mm) | 0.6 | 0.6 |

| Vertical Compressive Strength (Mpa) | 0.8 | 0.9 |

| Horizontal Compressive Strength (Mpa) | 0.32 | 0.4 |

| Density(g/cm³) | 0.5 | 0.44 |

| Specific surface area(㎡/g) | >900 | >900 |

| Adsorption rate of benzene(%) | >90 | >90 |

| Softening point(℃) | >900 | >900 |

Русский

Русский Français

Français Español

Español English

English

Welcome to send your message to us