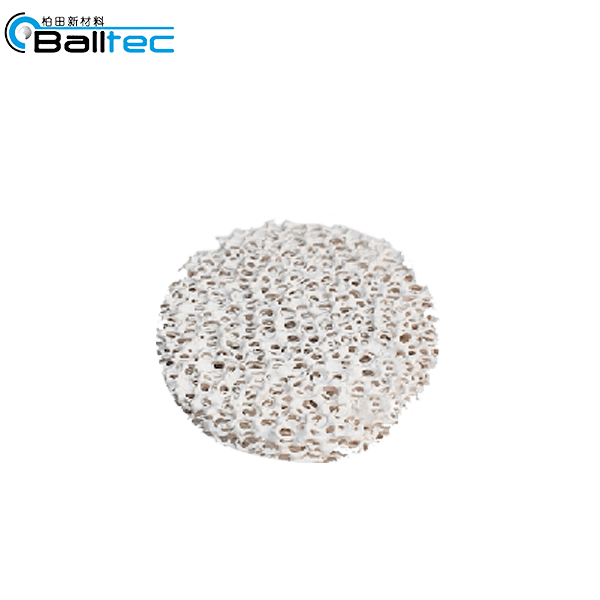

Zirconia Ceramic Foam Filters

Product Description

Ceramic foam is a tough foam made from ceramics. Manufacturing techniques include impregnating open-cell polymer foams internally with ceramic slurry and then firing in a kiln, leaving only ceramic material. The foams may consist of several ceramic materials such as aluminum oxide, a common high-temperature ceramic, and gets insulating properties from the many tiny air-filled voids within the material.

The foam can be used not only for thermal insulation, but also for a variety of other applications such as acoustic insulation, absorption of environmental pollutants, filtration of molten metal alloys, and as substrate for catalysts requiring large internal surface area.

Related Products

-

Zirconia Ceramic Foam Filters

Zirconia ceramic foam filters are used for molten all types of steel like unalloyed, low alloyed, stainless and high-alloyed as well as Nickel and Cobalt-based super-alloys. With their excellent resistance to attack and corrosion from molten steel liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner.

Details -

Silicon Carbide Ceramic Foam Filters

Silicon Carbide foundry foam ceramic filter is mainly for filtration of cast iron and non-ferrous alloys. With their excellent resistance against molten iron liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner.

Details -

Alumina Ceramic Foam Filters

Alumina Ceramic Foam Filters is available in all common sizes: 7", 9", 12", 15", 17", 20", and 23". We offers the whole range of porosities from PPI 10 up to PPI 60 (PPI = pores per inch). Custom-made cut-to-size filters are also possible. Alumina Ceramic Foam Filters is equipped with a gasket on the edges.

Details

Русский

Русский Français

Français Español

Español English

English

Welcome to send your message to us