- Home

- Products

- Ceramic Powder

- Zirconia Powder

High Quality Zirconia Powder Products >>>

Zirconium oxide (ZrO2), or zirconia, is an advanced ceramic material most commonly used in the production of different types of hard ceramics. This material is most widely used for production of various dental implants due to its hardness, chemical unreactivity, and its various biocompatible aspects.

However, zirconia’s use in dentistry is only the most well-known use of this advanced ceramic material. There are other properties that make zirconia suitable for various applications.

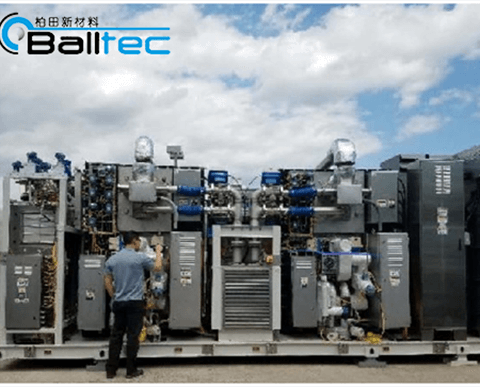

Zirconia is also used in Fluid handling

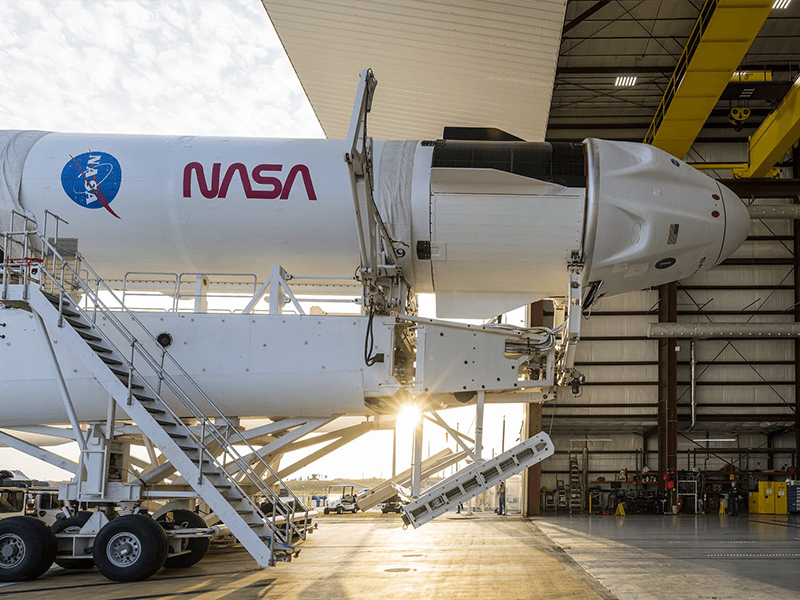

Aerospace Components

Aerospace Components

Related Products

-

Zirconia Powder for Grinding Media

Compared with alumina balls, glass balls and steel balls, the grinding media produced by using zirconia powder has high hardness, high toughness, good wear resistance, excellent grinding fineness, high efficiency, and extremely low wear. The material is pollution-free, and it is gradually replacing other grinding media, especially 0.1-0.5mm microbeads are widely used in ceramic ink, ink, color paste, dye, paint, paint, electronic materials, nanomaterials and other fine grinding industries.

Details -

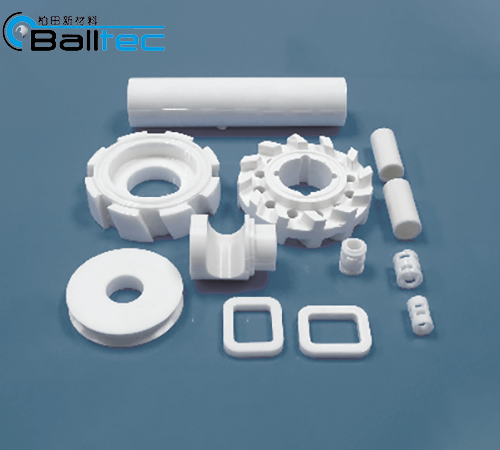

Zirconia Powder for High-end Structural Ceramics

High-end structural ceramics require that the microstructure of the material is basically defect-free, and the preparation process of its powder is designed by designing and controlling the microstructure of the material. This kind of powder shows features of easy molding, high strength, high toughness and anti-aging. Representative products are high-quality ceramic knives and ceramic sleeve bearings. Zirconia ceramic sleeve bearing is a new type of sleeve bearing with high temperature resistance, high pressure resistance, corrosion resistance and insulation.

Details -

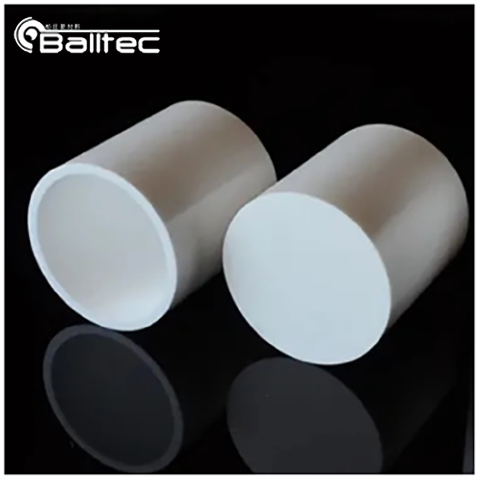

ZrO2 Powder for Ceramic Ferrule of Optical Fiber Connector

The zirconia ceramic ferrule is the core component of the optical fiber connector. It has always been the high-end application field of zirconia powder. This powder has the advantages of low sintering temperature, easy processing of the ferrule, high strength, anti-aging, and other advantages. Product quality Reach the international advanced level.

Details -

Dental Zirconia Powder

Zirconia is no allergy to the human oral cavity. Under the premise of reasonable design, it can be guaranteed for 50 years of use. Zirconia can be used in almost all denture designs, and it makes the length of the bridge unlimited. It is also the best material for dental implant technology. Dental zirconia powder has stress-induced phase transformation toughness and it is called tough ceramics. This powder has the advantages of high strength, high light transmittance and good biocompatibility, and the product quality has reached the international advanced level.

Details -

ZrO2 Powder for Oxygen Sensor

ZrO2 is oxygen-sensitive ceramics, also called oxygen concentration meter or oxygen sensor. Zirconium oxide acts as a solid electrolyte in the sensor when transmits electrons. It is mainly used in automobile exhaust, boiler exhaust and other places to control combustion, improve combustion efficiency and reduce air pollution.

Details -

Zirconia Powder for Electronic Ceramics

The powder for electronic ceramics is mainly based on pure zirconia, which reacts with other oxides to form ceramics with various functions, such as lead piezoelectric ceramics (ultrasonic motor, transducer, vibrator), microwave dielectric ceramics (microwave tuner), etc., are widely used in various electronic products.

Details -

Zirconia Powder for Solid Oxide Fuel Cell

Type: BT-SBT-10.0

Details

D50 (um): ≤0.30

SBET (S2/mg): 10.0-12.0

Sintered density (g/cm3):>5.70

Sintered Temperature (℃): 1350 -

ZrO2 Powder for Refractory Materials

Powder for Refractory Materials has high temperature resistance, good chemical stability, and strong corrosion resistance to acid and alkali slag, thus it’s not easy to decompose. In addition, it is an excellent special oxide refractory. 10mol% MgO stabilized zirconia powder is a commonly used in raw material.

Details -

Zirconia Powder for ZTA

Zirconia toughened alumina ceramics (composite ceramics, ZTA for short) are white in quality, corrosion resistant and chemically stable. Combining high hardness Alumina and good toughness zirconia, they form an excellent composite. It is a traditional material for textile ceramics. However, in recent years, with the successful application, the added value of the product is enhanced.

Details -

Black Zirconia Ceramic Powder

Utilizing special color-generating crystal grains, the white zirconia emits a dark and deep color, while inheriting the excellent mechanical properties of zirconia. It endows black zirconia ceramic with excellent properties such as high density, high strength, and few pinholes. The quality has reached the international advanced level, and it is widely used as the shell material of high-end consumer products.

Details -

ZrO2 Powder for Aesthetics & High-end Daily-use Porcelain

Zirconia ceramics have high strength, low thermal conductivity, and excellent texture. After special processing, they have good light transmission and beautiful appearance. They are ideal raw materials for high-end daily-use ceramics and aesthetic ceramics.

Details

Русский

Русский Français

Français Español

Español English

English

Welcome to send your message to us